What is r2fuel?

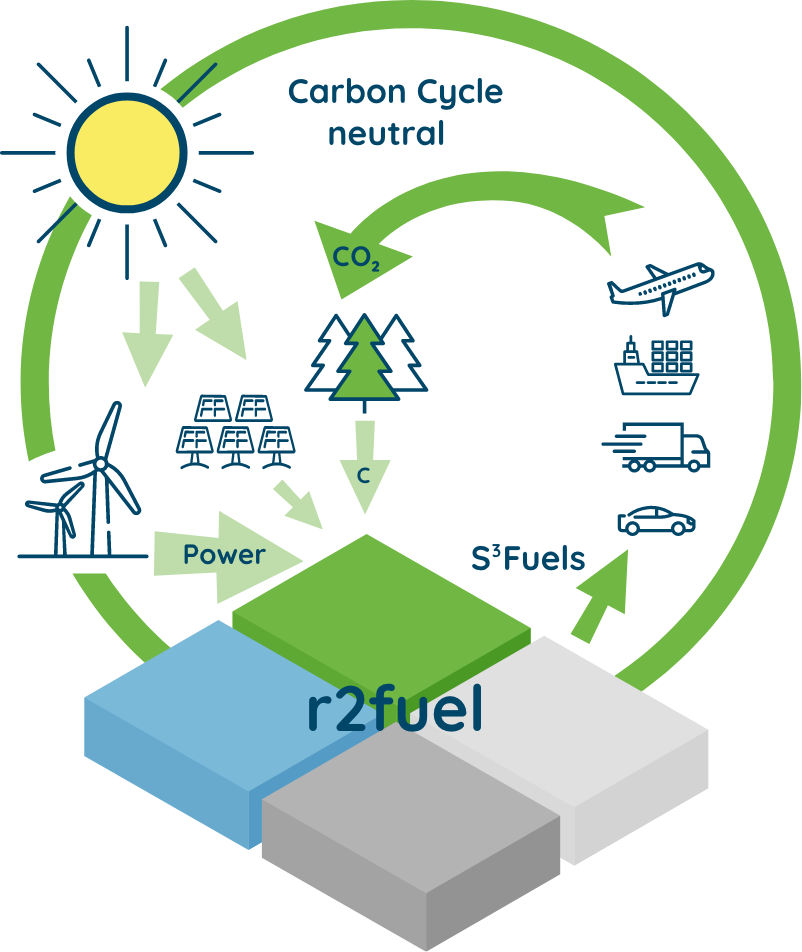

r2fuel stands for residues to fuel. The r2fuel system is an innovative solution for climate-neutral fuels from residual and waste materials for immediate use on location.

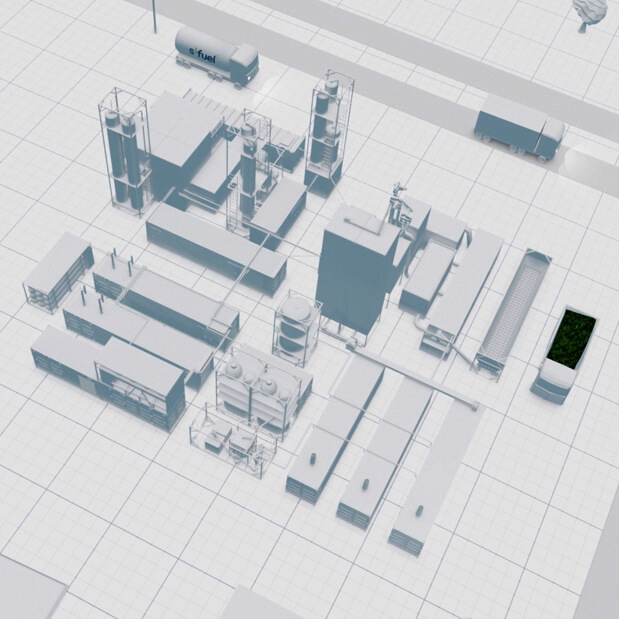

With a footprint of just 2,000 m², it is possible to produce CO₂-neutral, S³-Fuel from sewage sludge, wood- or agricultural residues by adapting the modular plant configuration. These fuels are suitable for conventional engines, without conversion.

As a company or municipality, do you have biogenic waste and residual materials that you want to recycle in a climate-neutral way? Then get in touch with us.

r2fuel – building blocks of the future.

Depending on the feedstock and the desired end product, the plants are optimally configured and manufactured.

Possible feedstocks

Sewage sludge

Digestion residues

Wood residues

Agricultural residues

Modules for whole process

Treatment of feedstock

Processing of waste and residual materials into a homogeneous, gasification-optimised feedstock in granulate form.

Syngas generation

The required CO₂ comes from the gasification of the conditioned feedstock.

Hydrogen electrolysis

The required hydrogen is produced by electrolysis using electricity from renewable sources.

Two-stage process with SynMethanol

SynMethanol is produced from CO₂ and H₂ in a continuous process. This is used to produce the fuels.

Possible end products

S³ fuels

S³ Gasoline

S³ Kerosene

S³ Methanol

S³ LPG

S³ DME

Basic chemical products

Basic materials for the chemical industry such as methanol

Benefits of the r2fuel system

Any questions?

How does an r2fuel plant work?

An r2fuel plant produces hydrogen from water and green electricity from solar or wind energy. With the help of the produced Hydrogen, bio-waste is used to further process the CO₂ contained in the waste in a so-called synthesis, instead of letting it end up unused in the atmosphere and contribute to climate change. The further processing in an r2fuel plant produces green fuel.

Why is it advantageous to use sewage sludge or other waste?

The use of these regionally produced residual materials – de facto wastes – with a very high carbon content from plants does not compete with their use as food, i.e. agricultural land is thus no longer used for fuel, but only for food. Moreover, this use of waste solves a serious and expensive disposal problem. For example, slurry no longer has to be spread on fields for disposal in huge quantities, thus quite proactively preventing overfertilisation of our fields and pollution of our groundwater reserves. And in the case of sewage sludge, but also waste wood, it makes both ecological and economic sense to use them in r2fuel plants. Another advantage is that long transport distances for the feedstocks and produced S³ fuels can be saved, as the r2fuel plants produce small and compactly in the middle of the region for the region, thus contributing to the desired development of a secure, decentralised and regional energy supply.

What end products can be produced with the r2fuel system?

The product range of the r2fuel plants includes the following S³ fuels: S³ methanol, S³ kerosene, S³ gasoline,

S³ DME, S³ LPG. In addition, the S³ methanol produced can also be used as a raw material in the chemical industry. Other fuels such as S³ diesel will be made available in the 2nd expansion stage.

What does S³ mean?

S³ stands for standardised (consistent properties), sustainable (CO₂-neutral), synthetic (chemically produced without the use of petroleum).

Why are S³ fuels climate-neutral and sustainable?

The production of S³-Fuels uses environmentally friendly electricity from wind and solar power, and the CO₂ required for synthesis comes from waste biomass or biogenic residues. This eliminates the use of fossil fuels and reduces further enrichment of the atmosphere with fossil CO₂.

Where can S³ methanol be used?

As an alcohol from sustainable production, S³ methanol can be used directly as a fuel in large combustion engines (after modification) and is a valuable base material for the chemical industry (e.g. for the production of acetic acid, ethylene, propylene, melamine resins, plastics, dyes).

Where are the advantages and preferred applications of S³-Kerosene?

S³-Kerosene as SAF (Sustainable Aviation Fuel) according to ASTM D7566 can be blended up to 50% with conventional Jet A or Jet A-1. Currently, S³-Kerosene can be used as a drop-in fuel. For 100% use of S³ Kerosene, manufacturers will need, among other things, adapted and certified aircraft turbines. S³ Kerosene from decentralised and compact r2fuel plants is especially well suited for use in regional airports with a high number of smaller commercial aircraft and business jets.

Get in touch with us

Are you interested in our r2fuel system? We will be happy to inform you about details.